Classification

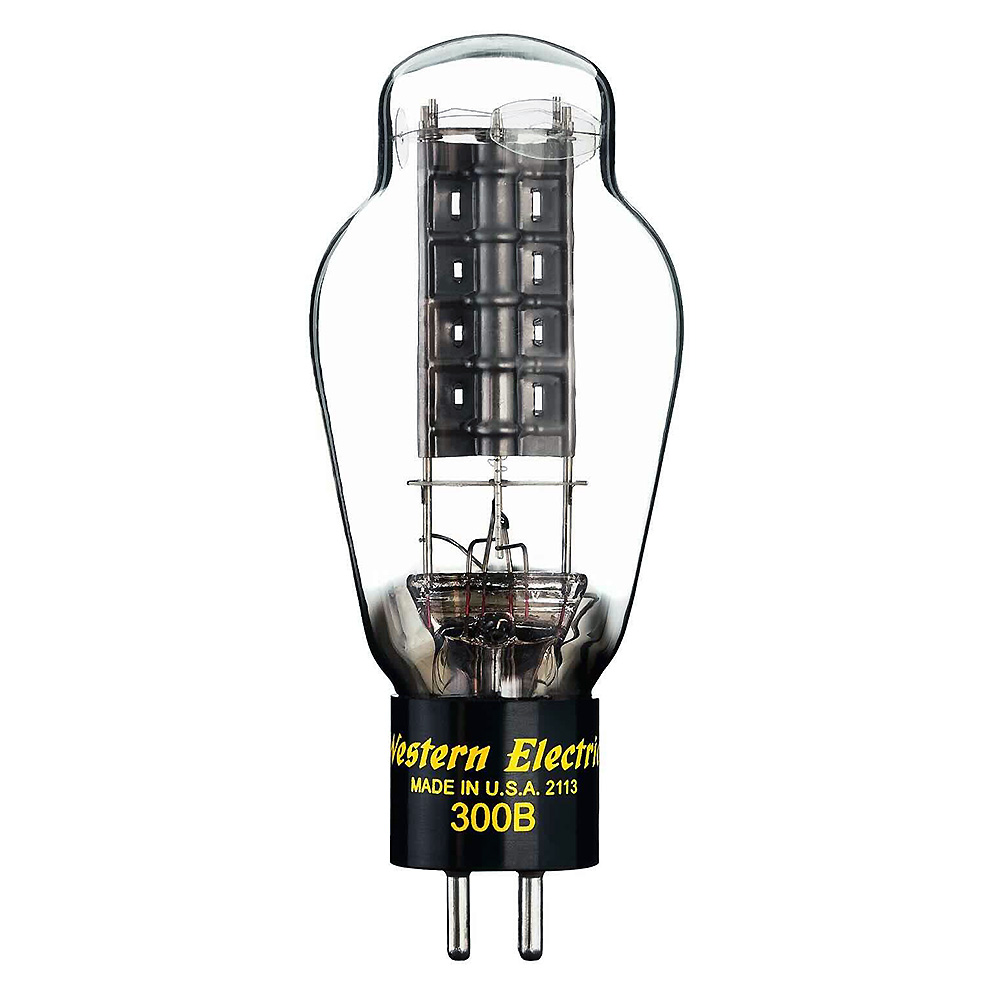

Moderate power, filamentary triodes for Class-A service.

Application

Audio-frequency amplifier in positions where power outputs of approximately ten watts or less are required at relatively low plate voltages.

Dimensions

Dimensions, outline diagrams of the tubes and bases, and the arrangement of electrode connections to the base terminals are shown in Figures 1 and 2.

Base and Mounting

These vacuum tubes employ medium, four-pin thrust type bases suitable for use in Western Electric 143B or similar sockets. The 300B tube has the bayonet pin so located that it may also be mounted in a Western Electric 100M, 115B, or similar socket.

The tubes may be mounted in either a vertical or horizontal position. If mounted In a horizontal position, the plane of the filament, which is indicated In Figure 2, should be vertical.

Average Direct Interelectrode Capacitances

Grid to plate 15 µµf.

Grid to filament 9 µµf.

Plate to filament 4.3 µµf.

Filament Rating

Filament voltage 5.0 volts, a.c. or d.c.

Nominal filament current 1.2 amperes

The filaments of these tubes are designed to operate on a voltage basis and should be operated at as near the rated voltage as possible. When alternating current is used for heating the filament, the grid and plate returns should be connected to a center tap on the secondary of the filament transformer.

Features

CHARACTERISTICS

Average Characteristics

(Ef = 5.0 volts, a.c., Eb = 300 volts and Ec = -61 volts)

Plate current 60 milliamperes

Amplification factor 3.85

Plate resistance 700 ohms

Grid to plate transconductance 5500 micromhos

Limiting Operating Conditions for Safe Operation

(Not simultaneous ratings)

Maximum plate voltage: 450 volts

Maximum plate dissipation: 40 watts

Maximum plate current of an average tube for fixed grid bias: 70 milliamperes

Maximum plate current for manually adjusted grid bias or self-biasing circuit: 100 milliamperes

Recommended Operating Conditions

Recommended and maximum conditions for alternating-current filament supply are given in the table. Recommended conditions or others of no greater severity should be selected in preference to maximum conditions wherever possible. The life of the tube at maximum operating conditions will be shorter than at the recommended conditions.

Where it is necessary to operate the tube at or near the maximum plate current of 100 milliamperes, provision should be made for adjusting the grid bias of each tube independently, so that the maximum safe plate current will not be exceeded in any tube. Alternatively, a self-biasing circuit may be used, in which the grid bias for the tube is obtained from the voltage drop produced by the plate current of that tube flowing through a resistance.

Where it is necessary to use a fixed grid bias, the plate current of the average tube should be limited to a maximum value of 70 milliamperes, so that tubes having plate currents higher than the average will not exceed the maximum safe plate current.

Power Output and Distortion

Performance data including power output, second and third harmonic levels for a number of operating conditions are given in the table.

The variation of power output and harmonic levels with load resistance for several values of operating plate current is shown in Figures 7, 8 and 9, for a plate voltage of 350 volts.

The peak value of the sinusoidal input voltage, Egm, which gives the indicated power output, Pm and harmonic levels, F2m and F3m for each point in both the curves and the table, is numerically equal to the grid biasing voltage at that point. For a smaller input voltage Eg, the approximate levels may be computed from the following relations.

P=Pm(Eg/Egm)^2

F2=F2m+20 log10(Eg/Egm)

F3=F3m+40 log10(Eg/Egm)

CHARACTERISTIC CURVES

Plate-current characteristics for a typical tube are shown in Figure 3 as functions of grid bias, for alternating-current filament supply. The corresponding amplification-factor, plate-resistance, and transconductance characteristics are given in Figures 4, 5 and 6, respectively. When direct-current filament supply is used, and the grid and plate returns are connected to the negative end of the filament, the same characteristics are applicable if 3.5 is subtracted from the numerical value of each grid bias.

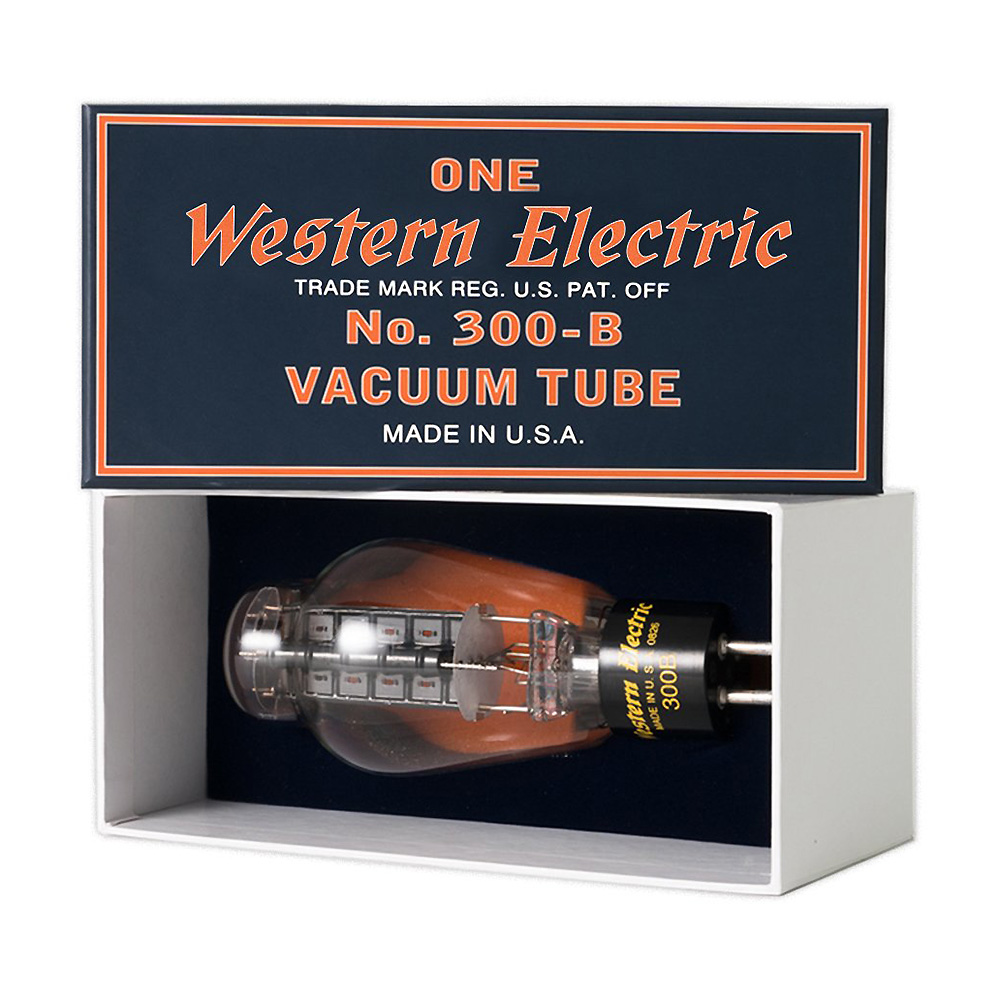

User Guide

Warranty

Electron tubes carry a Limited Warranty of ninety (90) days to the end user. The Limited Warranty period may be extended to five (5) years upon return of warranty card(s) included with your electron tube purchase. Warranty card(s) must be mailed within ten (10) days of purchase. Pre-addressed return envelopes included in each tube carton.

Reviews

There are no reviews yet.